The Importance of Attention to Detail in Laser Cutting Processes

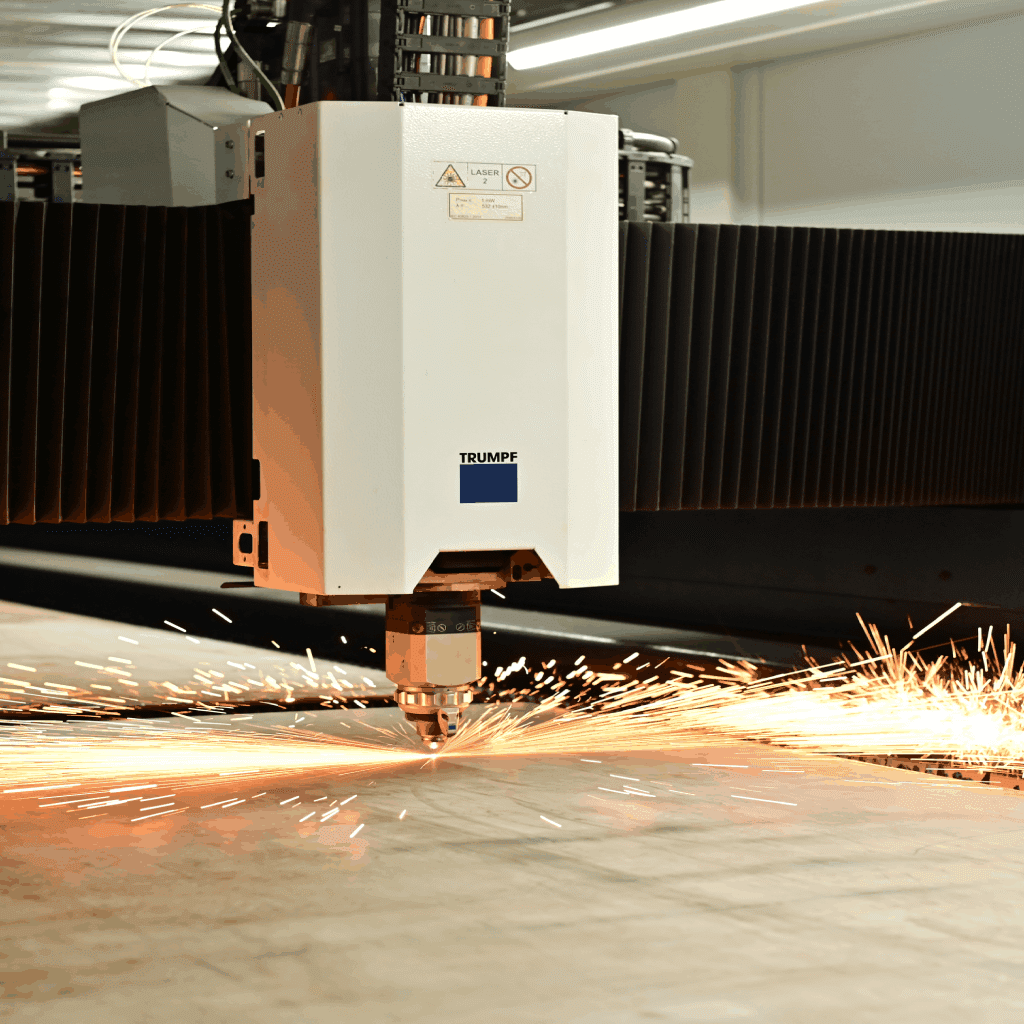

In the realm of manufacturing and engineering, precision is paramount. Laser cutting, a highly precise and versatile technology, has become a cornerstone of various industries. However, achieving exceptional results in laser cutting requires more than just advanced equipment and skilled operators. It necessitates meticulous attention to detail throughout the entire process. In this blog post, we will delve into the importance of attention to detail in laser cutting processes and how Advance Precitech upholds this crucial aspect to deliver superior results.

Material Selection and Preparation:

Attention to detail begins with the careful selection of materials. Different materials have unique properties that affect the laser cutting process, including the power settings, cutting speed, and focal length required. At Advance Precitech, we have extensive knowledge and experience in working with a wide range of materials, ensuring the appropriate selection for each project. Additionally, we meticulously prepare the materials, eliminating any contaminants or surface imperfections that could compromise the cutting precision.

Design and Programming:

Prior to initiating the laser cutting process, meticulous attention to detail is crucial during the design and programming stages. Our team of skilled engineers and technicians at Advance Precitech meticulously analyse and optimise the design files to ensure the precise translation of the desired outcomes. By meticulously examining the intricacies of the design, we identify any potential issues or areas that require special attention, enabling us to achieve exceptional precision during the cutting process.

Calibration and Maintenance of Laser Equipment:

To achieve consistent and accurate results, regular calibration and maintenance of laser cutting equipment are paramount. Advance Precitech places great emphasis on the calibration and maintenance of our laser machines, ensuring that they operate at their peak performance. Our technicians regularly monitor and adjust the laser power, beam alignment, and focus to maintain optimal cutting precision. By paying meticulous attention to equipment calibration, we guarantee the highest level of accuracy in every laser cutting project we undertake.

Quality Control and Inspection:

Attention to detail extends to comprehensive quality control and inspection processes. At Advance Precitech, we have stringent quality control measures in place to ensure that each cut piece meets the required specifications. Our skilled quality control personnel meticulously examine the finished products, checking for any deviations from the desired dimensions or any imperfections. By conducting thorough inspections, we maintain the highest level of precision and ensure that only flawless components are delivered to our clients.

Continuous Improvement and Customer Collaboration:

Advance Precitech is dedicated to continuous improvement in laser cutting processes. We actively seek customer feedback and collaborate closely with our clients to understand their specific requirements and expectations. This attention to detail enables us to tailor our laser cutting processes to meet their unique needs, ensuring that every project is executed with exceptional precision and accuracy.

Conclusion:

Attention to detail is the foundation of excellence in laser cutting processes. At Advance Precitech, we recognize the paramount importance of meticulousness in every aspect of laser cutting, from material selection and preparation to design, calibration, quality control, and customer collaboration. By upholding the highest standards of attention to detail, we consistently deliver superior results, providing our clients with precision-engineered components that meet and exceed their expectations.