Our Services

Download Brochures

Contact Us

Phone Number

+91 9766915151

enquiry@advanceprecitech.com

Address

J Block, Plot No. 166, MIDC, Bhosari

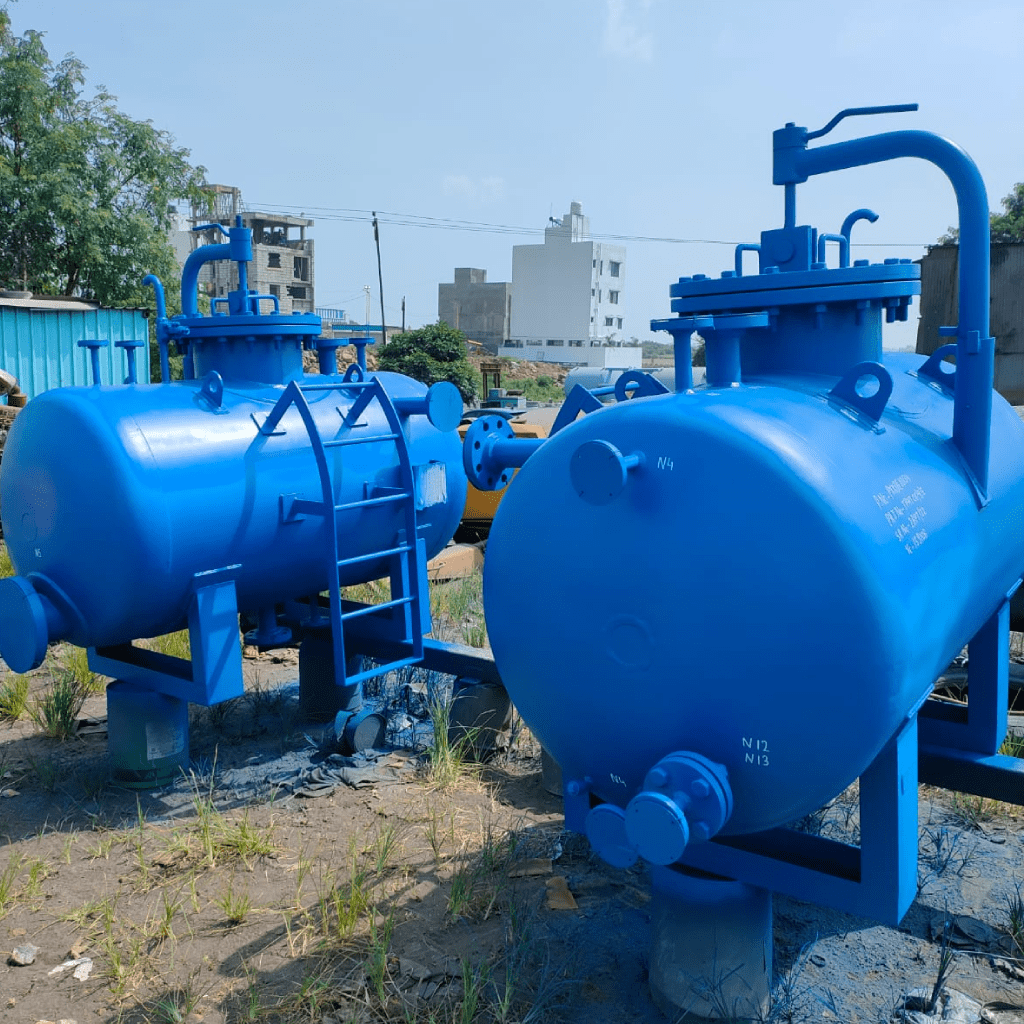

Pressure Vessel Fabrication Process

When assembling, fabricating, and tacking the welded metal parts in place during the construction of pressure vessels, some or all of the following steps may be required.

- First is the selection of raw materials commonly used for fabrication: plates, pipe, forgings, structural shapes, welding rods or wire, etc.

- After that is the cutting and burning of the raw material under the specified requirements,

- Then the machining of certain parts if needed. The assembling and welding of the pressure vessel parts are followed by cooling the weld and sandblasting it before applying primer and paint.

Quality Service

We develop complete engineering designs in-house based on Clients' natural engineering process data, and similarly, we work with clients' specified engineering packages and technical specifications. Our facilities are well suited to pressure vessel manufacture with vessels weighing up to 200 Tonnes fabricated weight completed recently.

What You Receive?

We work with our customers and ensure they are satisfied with their experience by finding ways to cut down on costs. We see various ways to reduce costs, including using the correct machine for each product, searching for methods of improving product features that cut costs and streamlining the material space to minimise scrap. Our laser-cutting services focus on meeting our customers' needs while creating efficient processes that reduce time and cost. Contact us to understand how we can customize our laser-cutting services to fit your manufacturing company.